VPS Visual Problem-Solving

Comprehensive Solutions That Last

If your problems are chronic, costly, and complex, if you want every employee to be a problem-solver, if cross-functional thinking is a cultural goal for your company, if you want solutions that last… then learn our VPS Method.

Many standard problem-solving approaches seek root-cause or silver-bullet solutions. That may work for snags and simplistic troubles—but what will help your company solve chronic, complex, costly problems that require comprehensive solutions that last?

Welcome to the VPS Visual Problem-Solving Methodology

The VPS Visual Problem-Solving Methodology* is a robust process that is designed to let companies:

- a) Systematically solve chronic, complex, and costly problems (aka, VPS problems);

- b) Implement many levels of sustainable solutions; and

- c) Build high-performing, cross-functional teams.

* Previously called “The ScoreBoarding Method.”

During the 3-Day Training Workshop.

The VPS-Method is driven through project teams, following VPS’s step-by-step process of detailed problem analysis, interactive solution-making, and accountability that promotes team and individual follow-through.

- Many VPS-Projects focus on persistent lead-time issues, such as bad quality and/or low productivity.

- VPS’s highly-structured method is ideal for reliably finding and achieving innovative outcomes—for example, related to product and process development and design.

- VPS-Projects are devised to achieve their targets within 90 days.

- Incremental targets are installed for longer-term outcomes.

- VPS-Teams focus on systematic fact-finding, not fault-finding—and comprehensive solution-making, not mere brainstorming or jumping to conclusions.

- Problems are deliberately segmented to make them small enough for teams to get their arms around and solve thoroughly.

- Causes are systematically linked to solutions which are then vetted, tested, and tracked before adoption.

- While some solutions are low-risk/low-effort, others are high-impact and need the careful deployment that the VPS-Method systematically provides.

- Project teams learn to work with discipline, self-accountability, and a bias for action.

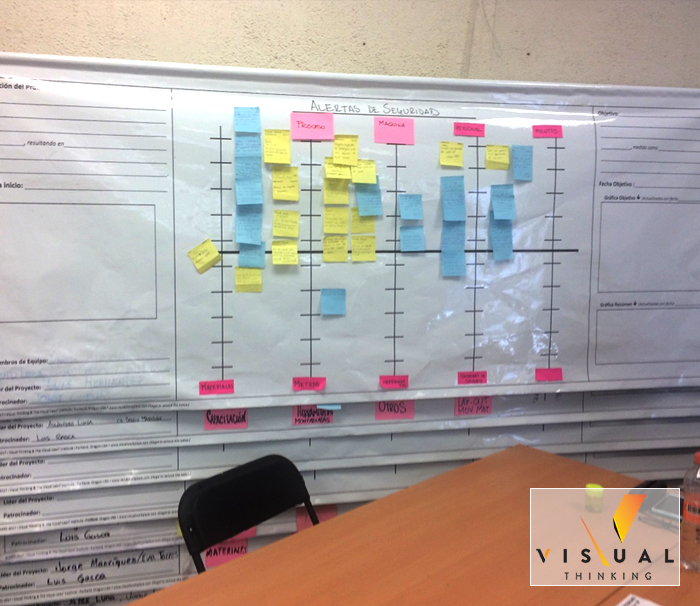

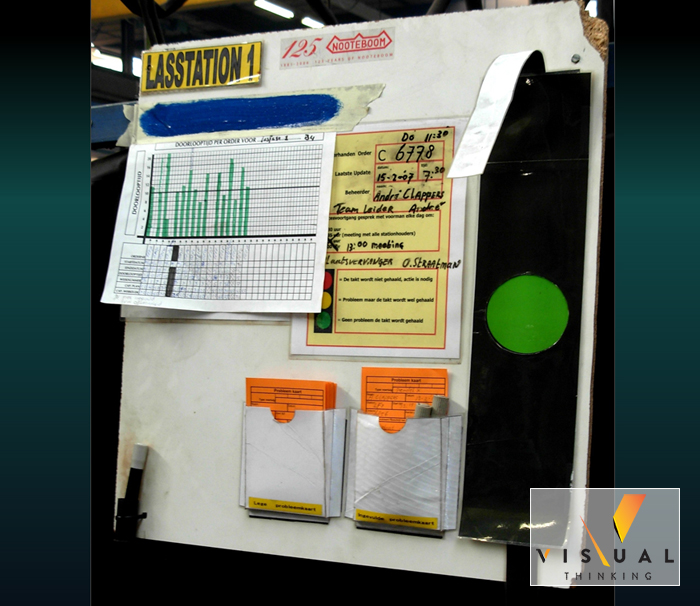

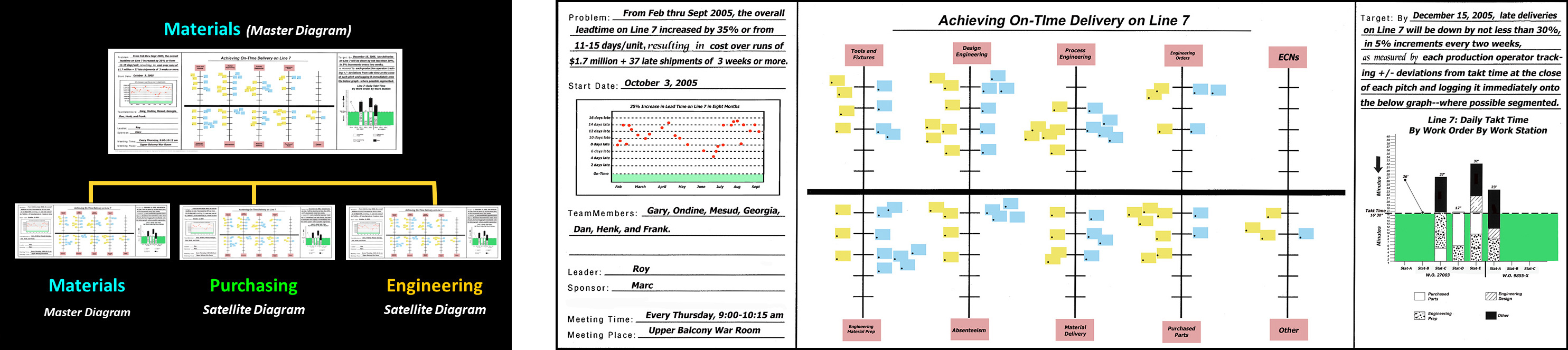

- The highly-visual/highly-structured VPS-Diagram is at the heart of the VPS’s visual problem-solving process.

- Using a visual paradigm of human behavior, specific VPS steps are taken to ensure that all solutions are visually deployed and visually sustainable.

- Through the VPS-Method, many key high-performance practices become a part of the company improvement mind-set—including a growing allegiance to the process (not to home departments) and a commitment to the next operation as the customer.

The VPS-Process builds improvement leadership on enterprise, department, and personal levels.

Who Attends.

The VPS-Workshop is best attended by improvement-minded people who want to lead improvement projects that promote and deploy systematic problem-solving and solution-making that lasts. The three workshop days are specifically designed for companies that want to train managers, supervisors, team leads, engineers, trainers, and/or CI specialists in a structured problem-solving method that is highly visual, led, and collaborative. Actual VPS-Projects are launched as part of this workshop.

Contact us.

Workshop Specifications.

Your VPS-Workshop is an intense, 3-Day hands-on training.

- On day-1, participants learn core VPS-concepts and principles. Then they focus on the 10 Steps of the VPS-Visual Problem-Solving Method. They build a VPS-Diagram for their own problem projects.

- On the second day, participants complete their VPS-Diagrams. Then they learn and practice VPS-Project Leader behaviors: a) for developing Cause Cards that describe their VPS-Problem in detail; and b) for generating robust solutions to their VPS-Problems.

- During day-3, not less than three pairs of VPS-Project Leaders launch their first VPS Sessions in real-time, teamed with the actual employees who will engage in solving the associated VPS-Problems. Teams activate their VPS-Diagrams.

- The workshop concludes with mapping out next steps.

- Group size: Seven pairs of VPS-Project Leaders/Assistant Leaders, pre-selected by the company to solve its most pressing problems.

- 14 active participants (up to 10 non-active observers are permitted)

Your fee includes.

- Five onsite follow-up visits, during which we observe, support, and troubleshoot the problem-solving progress of each of your five to seven VPS-Projects.

- Two online coaching sessions with Dr. Galsworth providing clarification, reinforcement training, and troubleshooting.

- A complete VPS Participant Manual for each active participants and observers (150 pages).

- A digital VPS-Resource Folio with electronic forms, exercises, checklists, and print-ready VPS-Digrams which you can produce at will.

Contact Us.

Kindly contact us with your questions or when you are ready to schedule your first VPS-Visual Problem-Solving Workshop. Contact us.