Description

$3,890.00

Until now, it could take years for a company to develop skill in mistake-proofing. Even then, what you learned usually endorsed out-of-date concepts and tools—and never addressed the real problem.

The Engineer’s Course

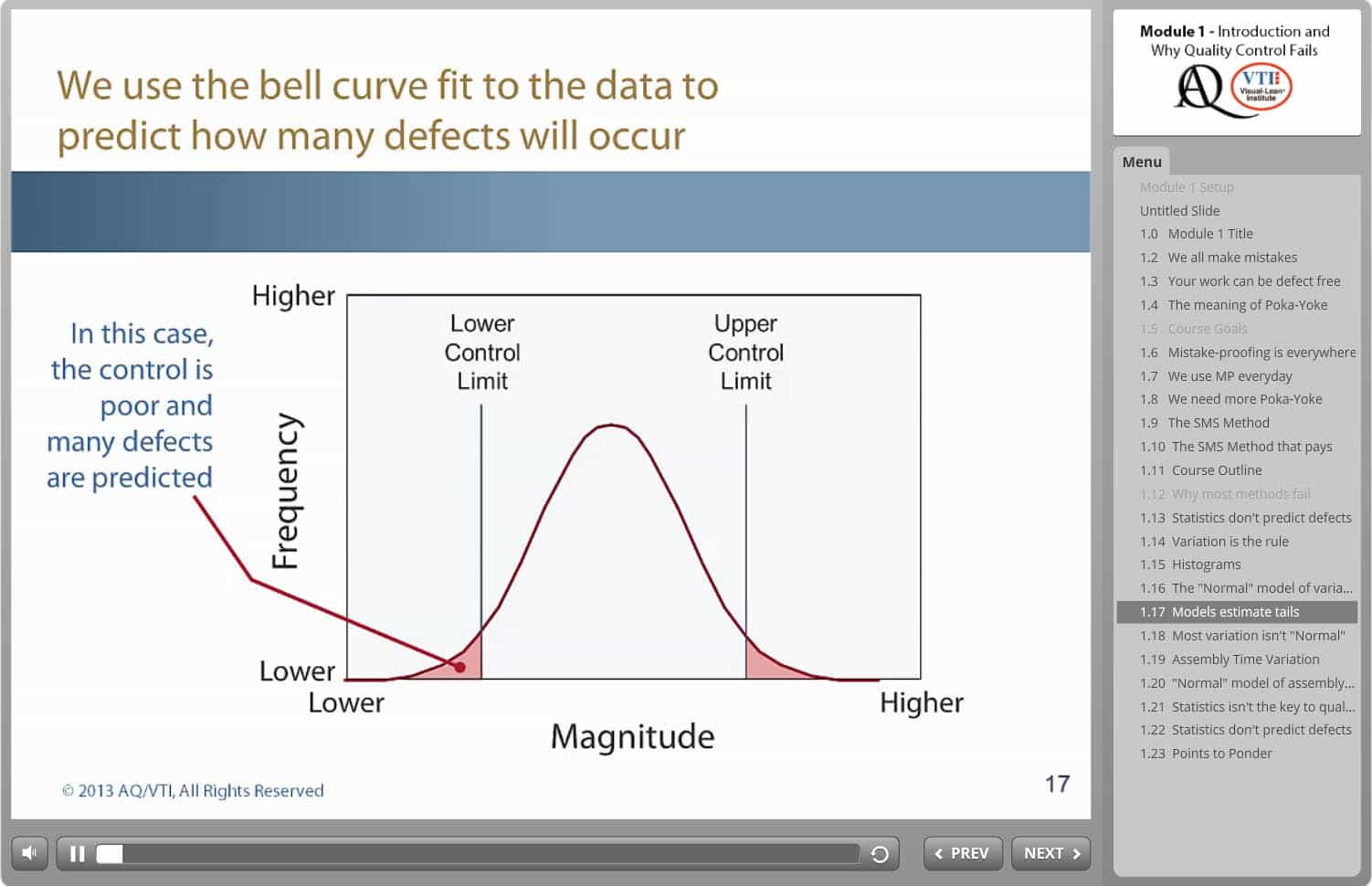

1 Why Most Quality Control Fails

2 The Exceptional Challenge of Mistakes

3 The SMS Method to World-Class Quality

4 Preventing Mistakes through Simplicity

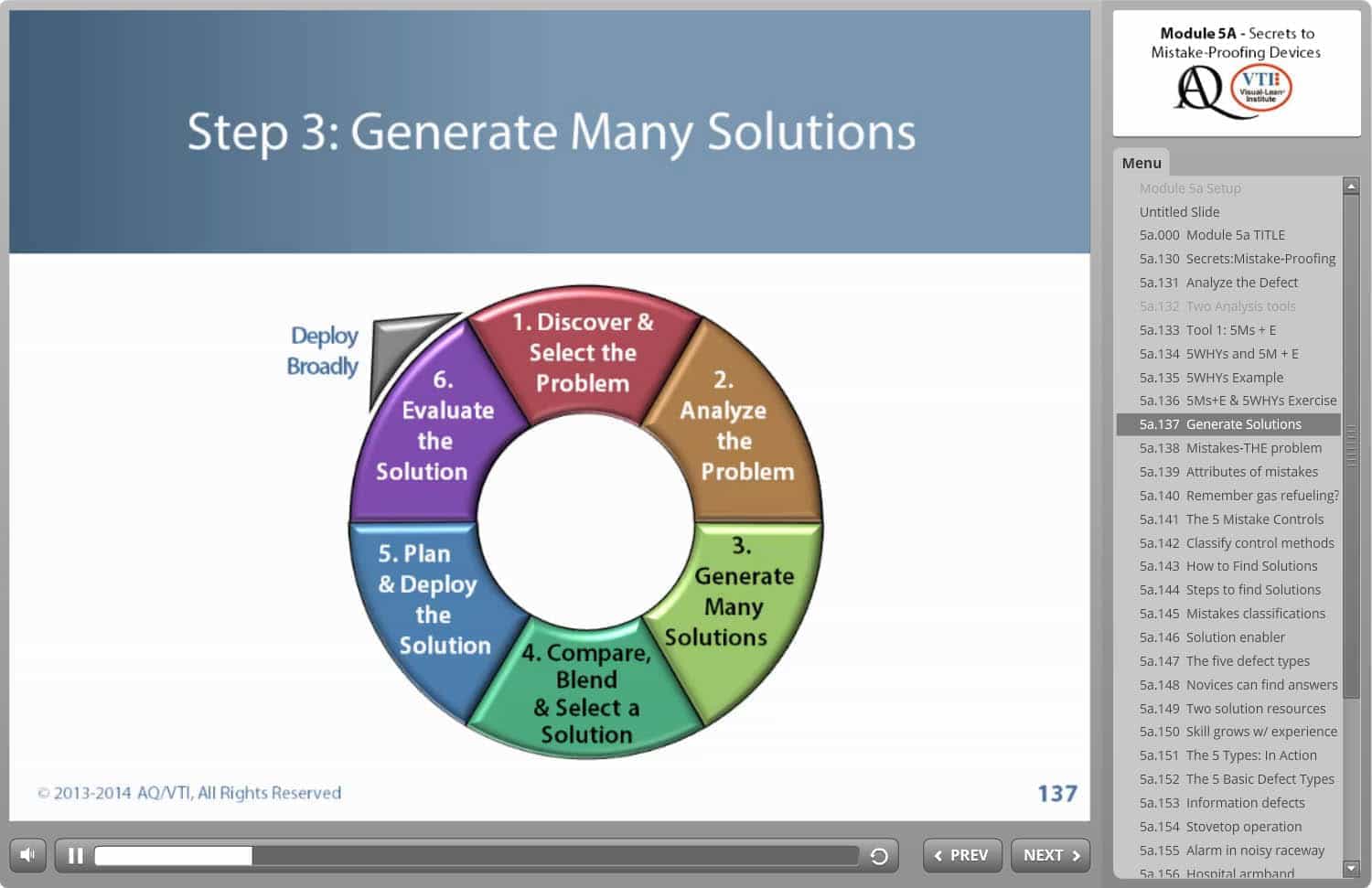

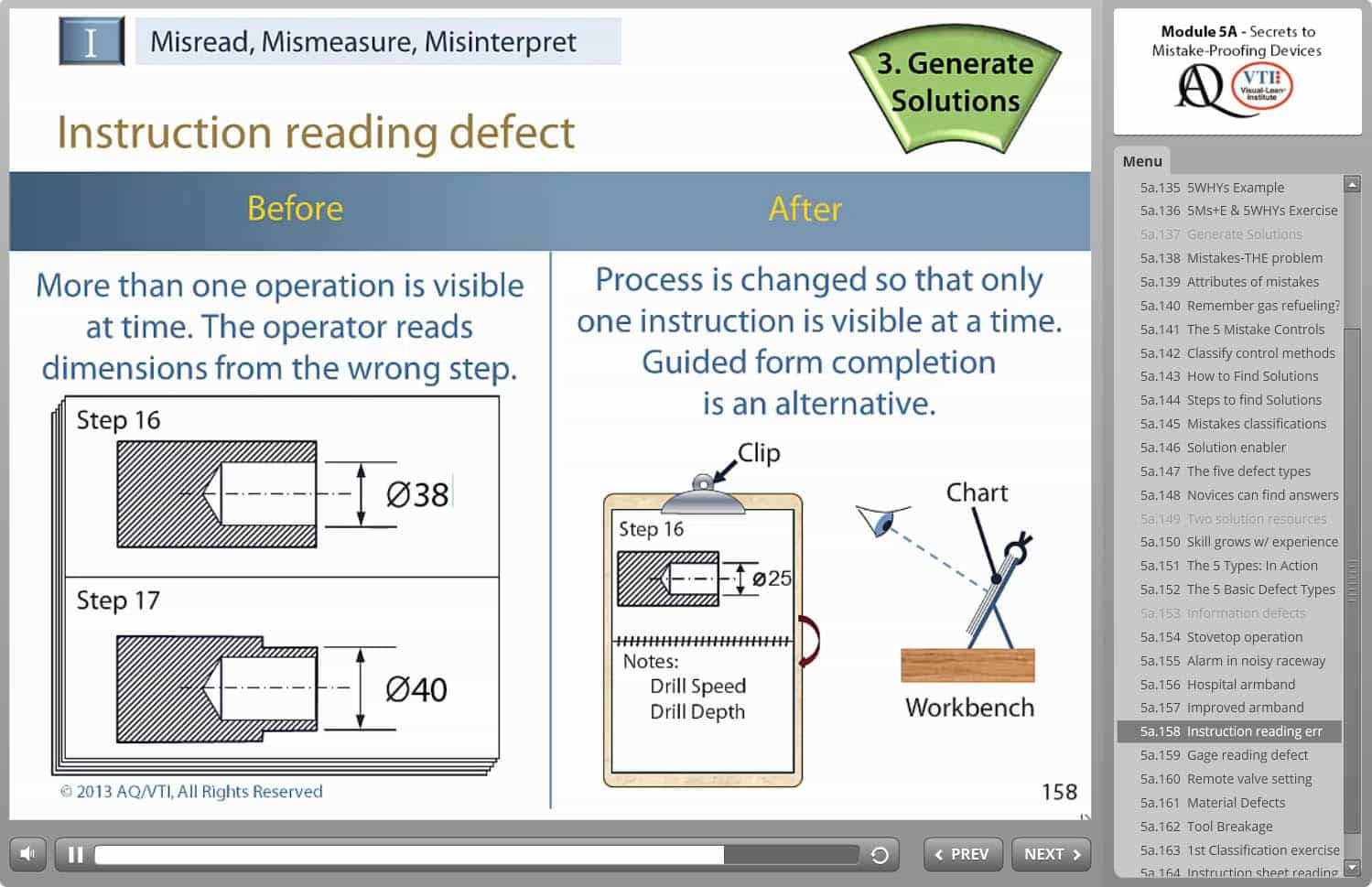

5 Secrets to Mistake-Proofing Devices (part 1)

6 Secrets to Mistake-Proofing Devices (part 2)

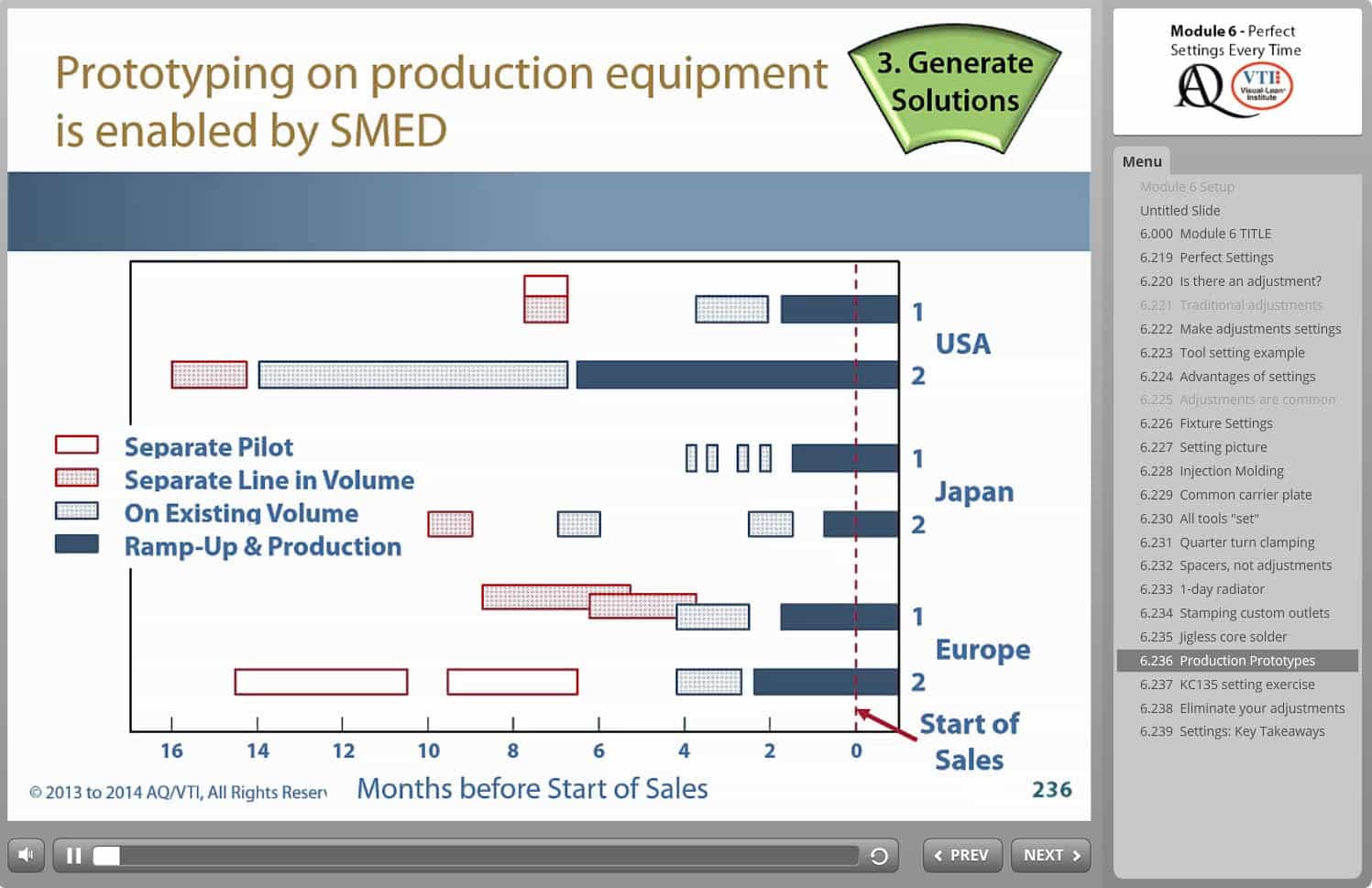

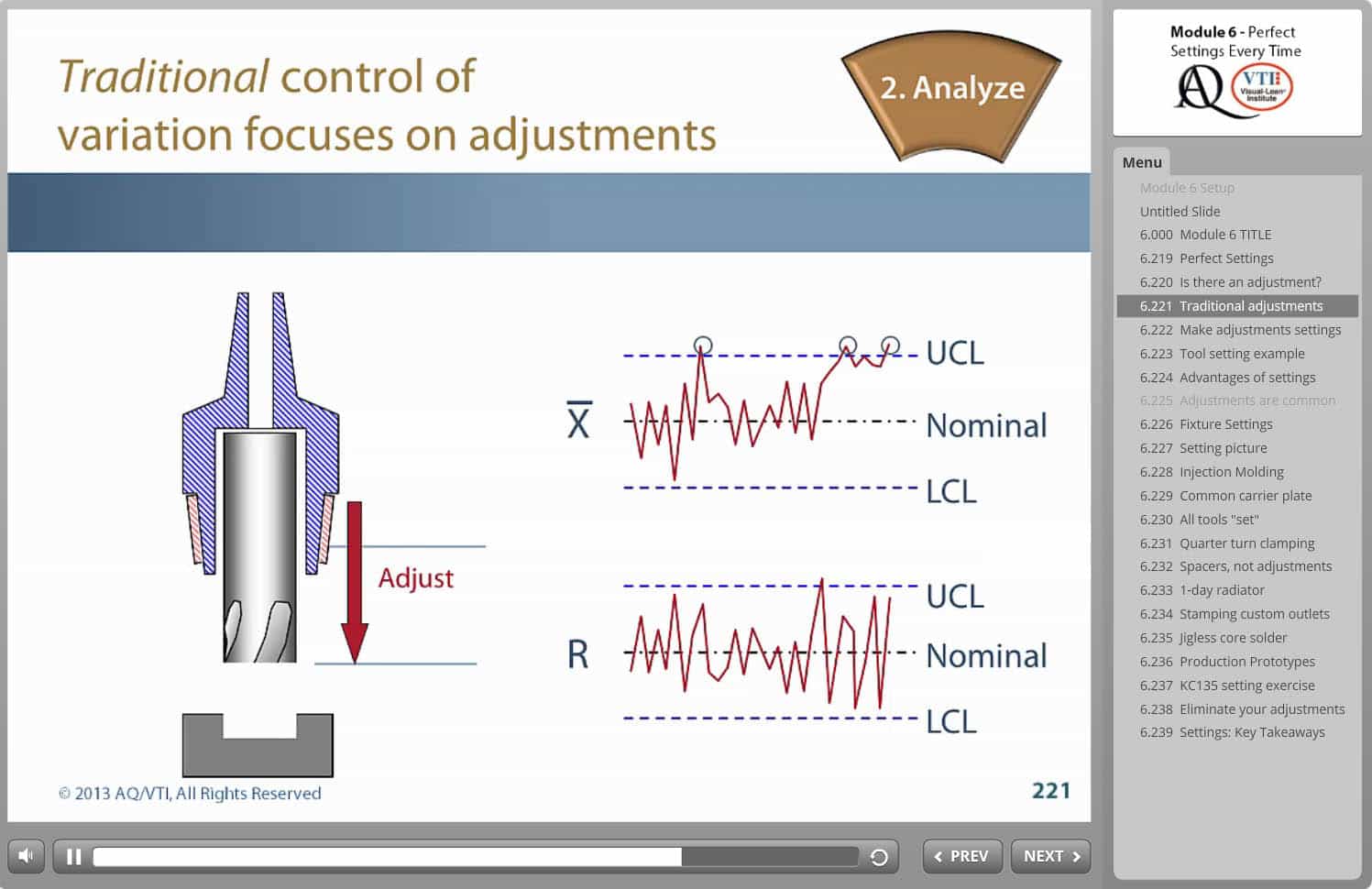

7 Perfect Settings Every Time

8 Great Solutions Deployed Every Time

Description

Now learn how to permanently eliminate defects from design and production through our powerful SMS Method for Engineers.

Co-developed by leading experts, Dr. Martin Hinckley (author of Make No Mistake) and Dr. Gwendolyn Galsworth (author of Smart Simple Design and Work That Makes Sense), this comprehensive eight-module training course teaches you and your engineers how to eliminate defects permanently through mistake-proofing—from concept to consumer, from design to operations. Watch your design and process engineering teams grow stronger, more aligned, and more effective—and your quality soar!

Contrary to popular thinking, variation is not the source of defects—mistakes are. Rely on statistical process control and you will be disappointed. The key to perfect product and process quality is our SMS methodology: Simplify, Mistake-proof, and Set Settings. It’s time to rethink your approach.

Unlike other approaches to mistake-proofing, our method doesn’t just show you examples. We teach you the logic, the method, and the system behind the solutions so you can independently create innovative solutions to ALL your own quality challenges–reliably, repeatedly, and precisely.

Additional information

| Delivery Method | Online learning via Litmos platform. |

|---|---|

| Additional Licenses | Visual Thinking Inc. will contact you to coordinate any additional licenses purchased for end-users and trainers. |