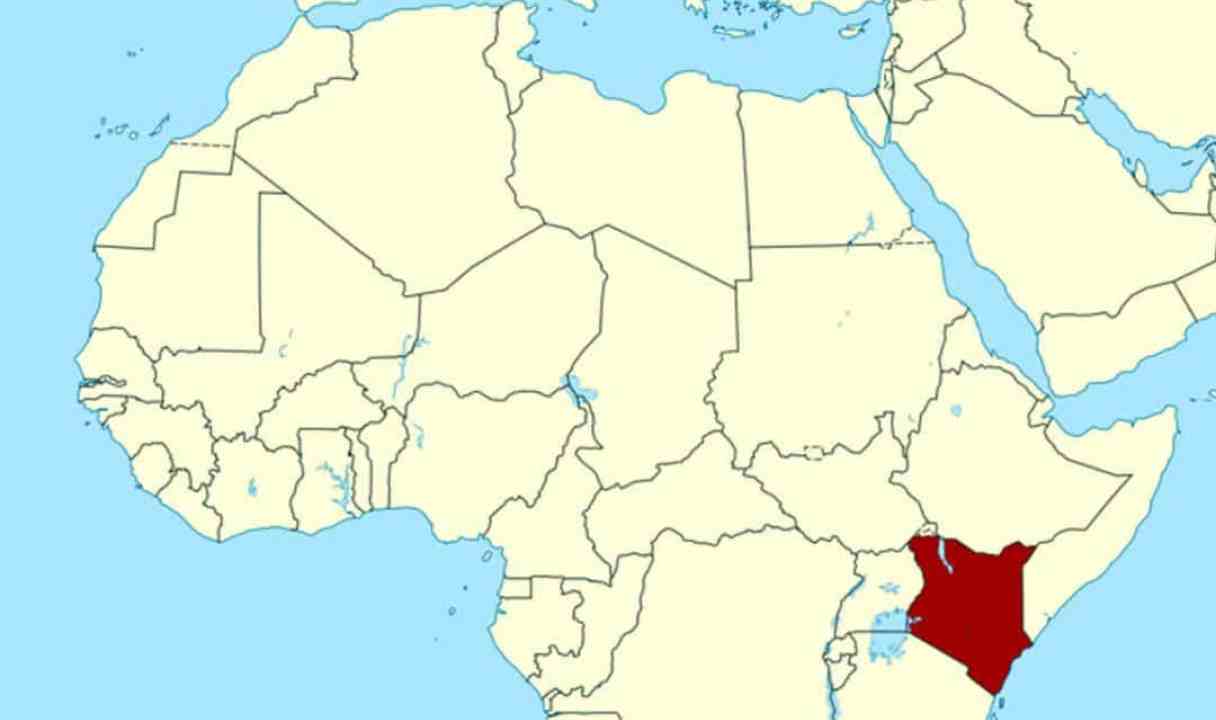

KENYA AND KAIZEN: A REMARKABLE ENCOUNTER

I’d like to tell you about my trip to sub-Saharan Africa. My first time. I had been invited to deliver a keynote at the 11th annual Kaizen conference, sponsored by The Kaizen Institute and KAM (Kenyan Association Manufacturing) in Nairobi, Kenya. That morphed on the second day into a seminar on Visual Thinking. This was not my usual keynote or seminar. Not for me. It was special because I had the great pleasure of meeting over 100 very savvy practitioners of continuous improvement, lean, and workplace visuality, with gurus Vinod Grover and Jayanth Murthy taking the lead.

Over the course of the first day, I got to listen to many case studies from African companies that had been on the improvement journey, some for as long as a decade. Here’s a sample of what I learned.

- Kariki Farms: Meeting the flower demands of Europe is the challenge the 1200 employees at Kariki Farms face every day. Correction: not employees but value-adders. “Innovation is easy,” we learned, “maintaining standards is difficult.” Eunice Mbuga, Group HR Manager, was joined on the podium by co-founder/CEO, Richard Fernandes, and Josphine Karega. “You have to really believe in your value-adders. You have to trust them, recognize them, and, most of all, appreciate them.” We all agree!

- Coninx: MD Nihal Shah revealed two of Coninx’s keys to creating a culture of entrepreneurs. The first: gamify work—set daily, weekly, and quarterly wins…and go after them. The second: reading—read books. Reading books is “a core value for personal and corporate growth.” Everyone reads from the same book list, together and in order. Everyone shares and applies what’s on the page. Everyone learns. The company grows, as does everyone who works in it. I was blown away. Aren’t you?

- Ubbink: Haijo Kuper, MD, was joined by Bernard Gachomba and Martin Mutinda. Ubbink, a solar panel manufacturer, grows teams and the people in them. As part of this, it implemented a Japanese-style suggestion approach called Teian—but with a twist. The person suggesting an idea is called the proposer, not the suggester. “After all,” Kuper pointed out, “You don’t suggest marriage. You propose it!” And whoever proposes a teian (improvement idea) implements it. “How many Teian cards did you implement this month?” Excellent!

- Transcorp Hilton: When the very capable Okaima ‘Keke Ohizua (Executive Director/Customer Service/Hilton Group) started the improvement journey she knew she faced the “Been There/Done That/Got the T-Shirt” challenge. So she focused on helping the people in room service, housekeeping, and engineering improve their work by seeing that work differently—visually. In the laundry, for example, separating linens into color-coded bags cut down that task by half: 2.5 hours, instead of 5.0 hours. Ms. Ohizua promised to send me a photo of those bags. When she does, we‘ll share it with you.

Hearing these conference speakers (and many others), it was a stretch for me to consider Kenya simply a developing country. These companies were acute in their understanding of kaizen, process improvement, results KPIs and process KPIs, and the people side of success. Their understanding was world-class and their application quickly approaching the same. Here is our group photo. (I’ll tell you about the safari part of this fabulous trip next week—with lots of photos of lions, elephants, and zebras, close up.)

![]()